A Dallas Designer Will Make Thousands of Free Surgical Masks for Those on the COVID-19 Frontlines

Jean Liu Tapped the Design Community to Help Produce Vital Gear

BY Rebecca Sherman // 03.22.20

Dallas interior designer Jean Liu

On Monday, Dallas designer Jean Liu will turn her Michigan-based outdoor furniture company, Woodard, into a manufacturer of non-medical-grade face masks, churning out thousands of desperately needed masks free of charge for those on the front lines of the COVID-19 emergency. There are critical shortages of masks and other protective gear as thousands of people infected with the disease have overwhelmed hospitals around the country. Doctors, nurses, and first-responders are making heart-wrenching public pleas for help.

Liu, a top interior designer and fixture on the Dallas and New York social scenes, took matters in her own hands Thursday night.

“My husband told me about a conversation he had with his cousin, who works at Mass General in Boston,” Liu says. “She was wearing the same mask over and over and pouring alcohol on it to make it last.” The situation so outraged Liu that she placed a call at 10 pm that night to Woodard’s plant manager, Louie Zelenka, enlisting his help.

“By 9 the next morning .we had a prototype,” she says.

On Friday, Liu enlisted Schumacher and Kravet to donate the tightly woven cotton for the masks; Century Furniture, CR Laine Furniture, and many others also joined the initiative and are using their automated cutting machines and sizable sewing teams to produce masks. Together they can make 10,000 masks a day. “We’re going to crank out as many of these masks as we can,” says Liu.

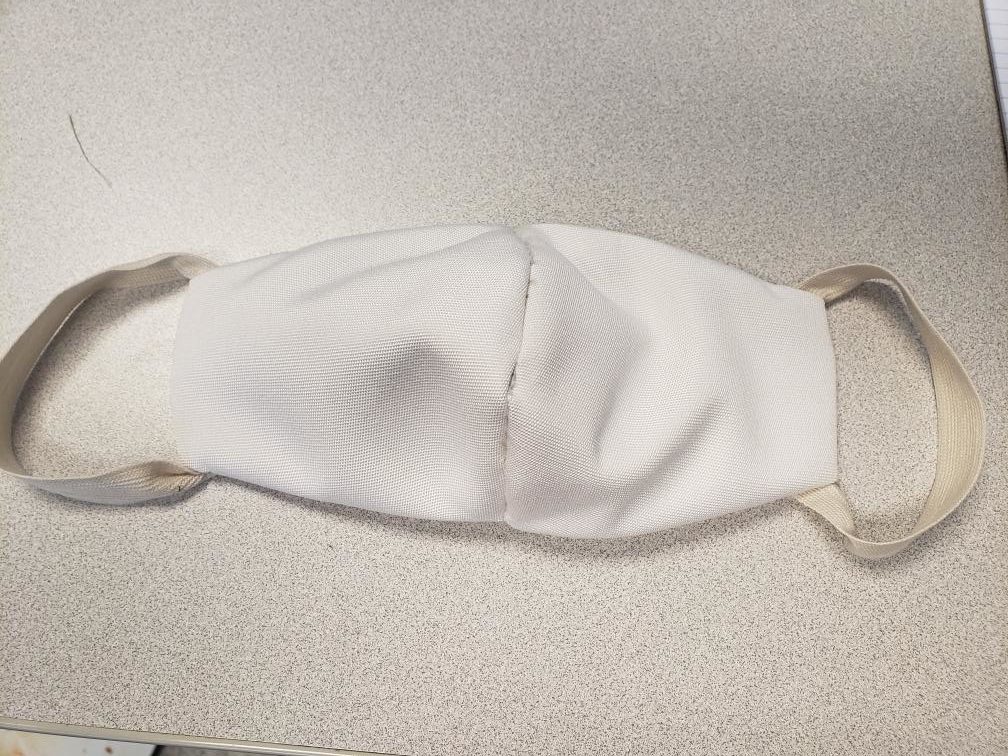

Zelenka made the surgical mask prototype from a “recipe” posted by Deaconess, a 125-year-old hospital and health services company, Liu says. The disposable masks are made from double-sided, tight-knight cotton weave and will be used to cover the more effective N95 masks, which will make them last longer. N95 masks filter out 95 percent of particles in the air and are often used by medical personnel, construction workers, and painters.

“Some hospitals don’t even have N95 masks, so they’ll be using them instead of bandanas, which is what a lot of them have been forced to resort to,” she says.

Liu’s efforts have already caught national attention, including a mention in a story on Saturday in The New York Times about private companies such as Hanes stepping in to produce surgical masks and other protective gear. As we spoke, Liu was preparing for a live interview on MSNBC.

Hospitals and medical personnel should go to the Woodard website, woodard-furniture.com, for further information on the masks.

“We are going to field requests as they come in,” Liu says. “One of the things we are doing today is to get on a call and figure out distribution — do we start with the hot zones like the Eastern seaboard and California, and move in from there? We’ll certainly be looking at filling the needs in our own communities.”

Liu is now researching how to manufacture other types of personal protective equipment.

“It’s hard to sit around and do nothing when you have the capabilities to do something,” she says. “These doctors and nurses feel like they’re on their own, and they need our help. It’s not war, but it sure feels like it.”

_md.jpeg)